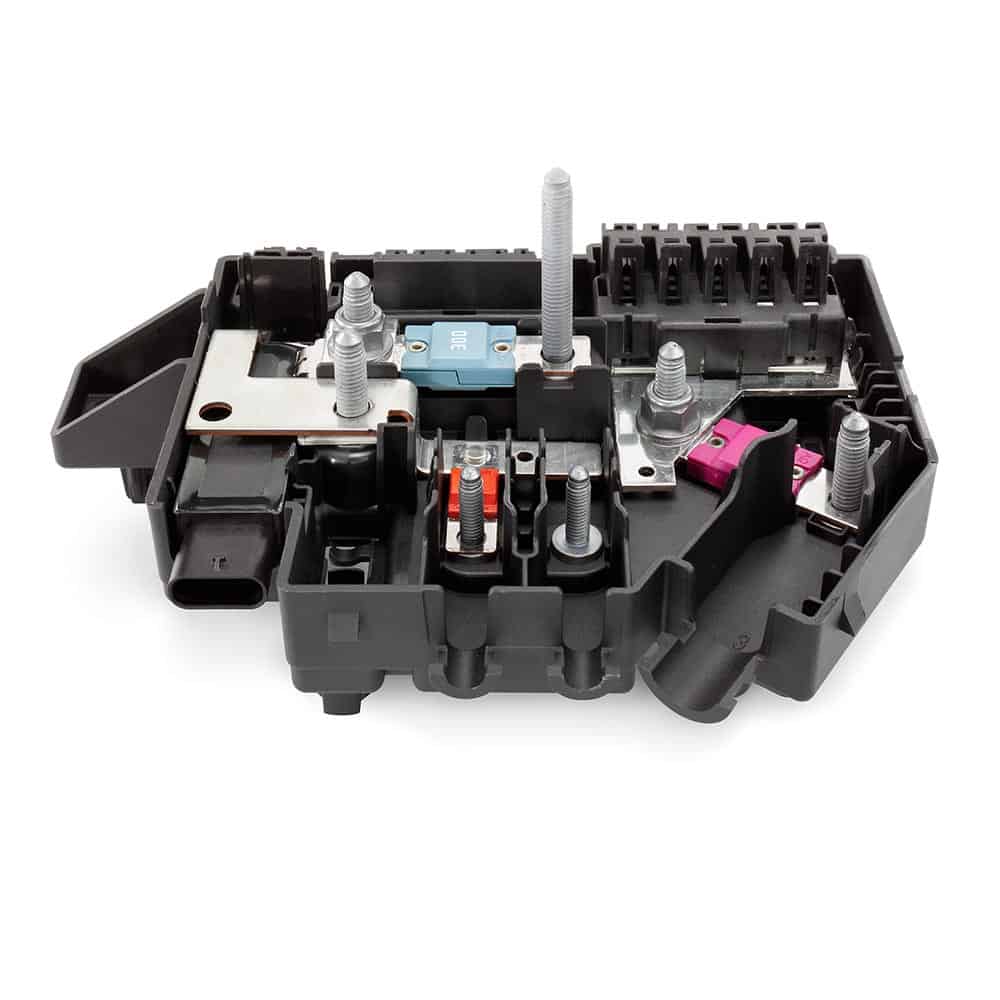

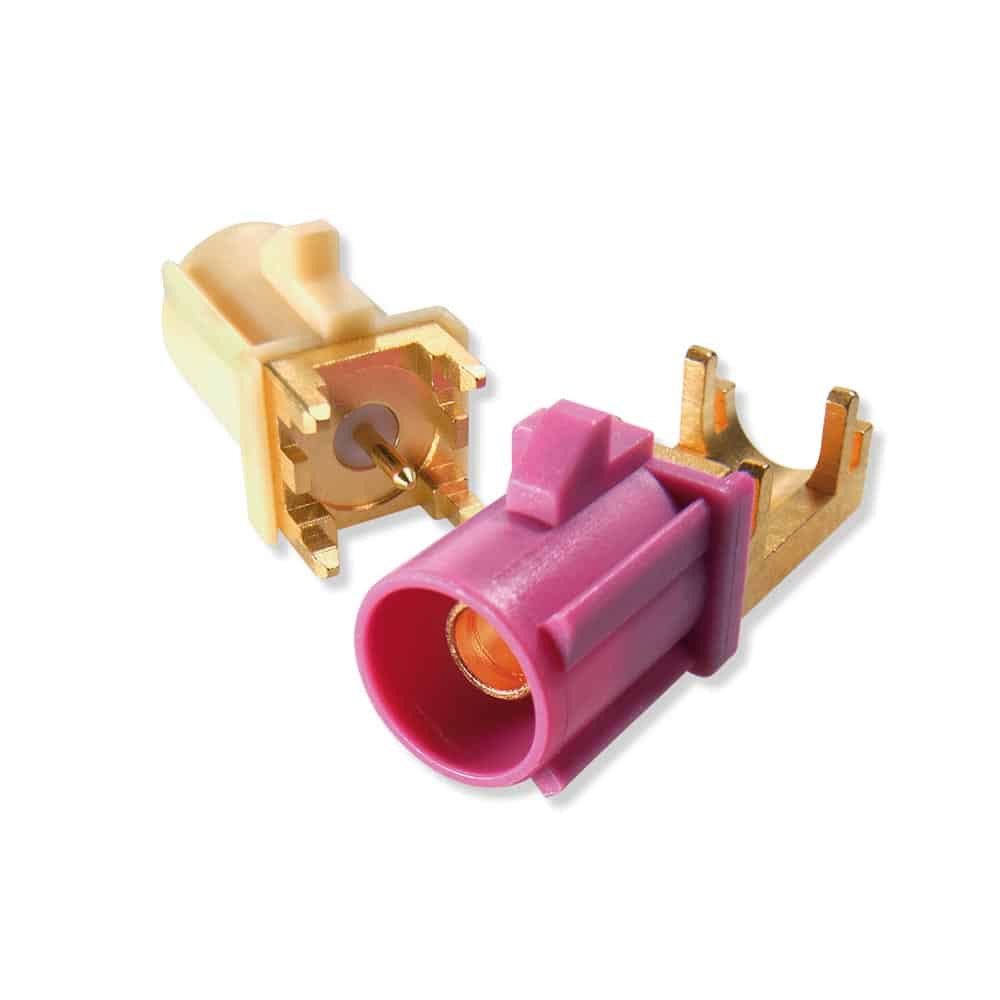

Automotive & (E-)Mobility

Products for established as well as innovative drive technologies and vehicles – even including autonomous mobility.

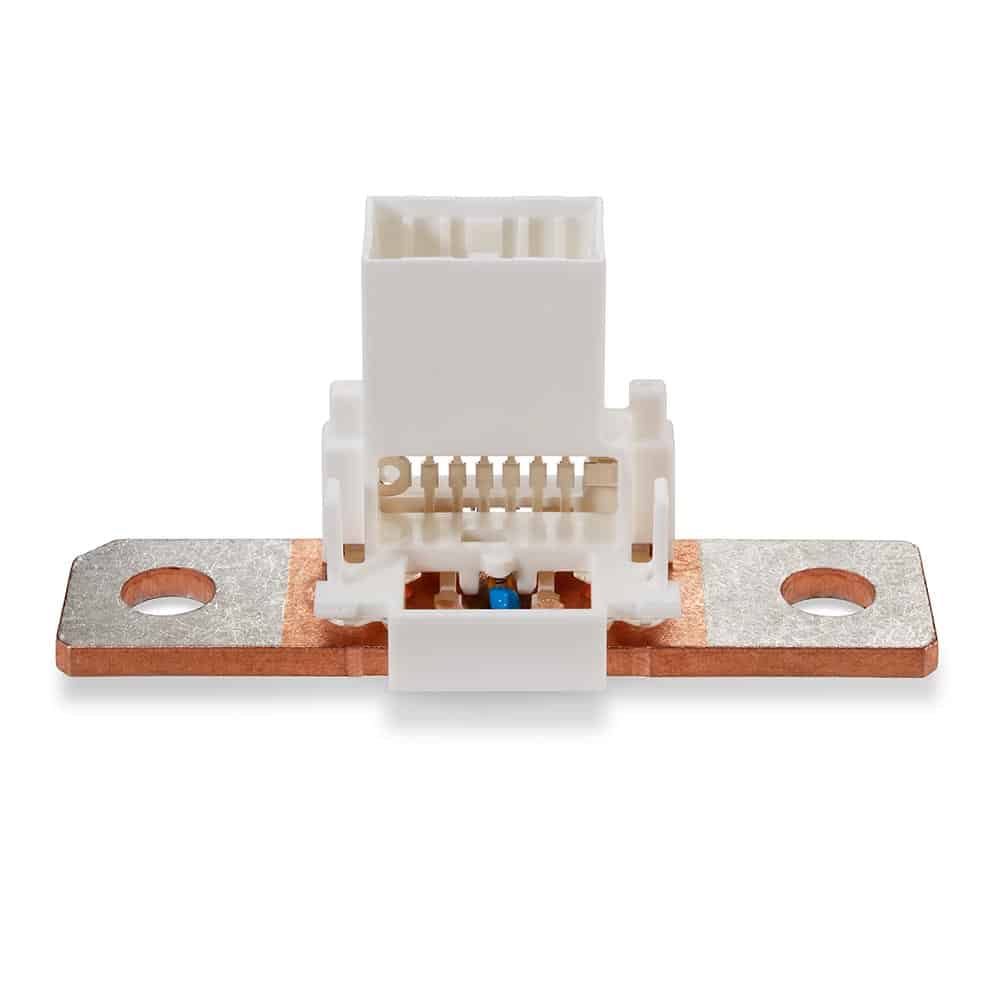

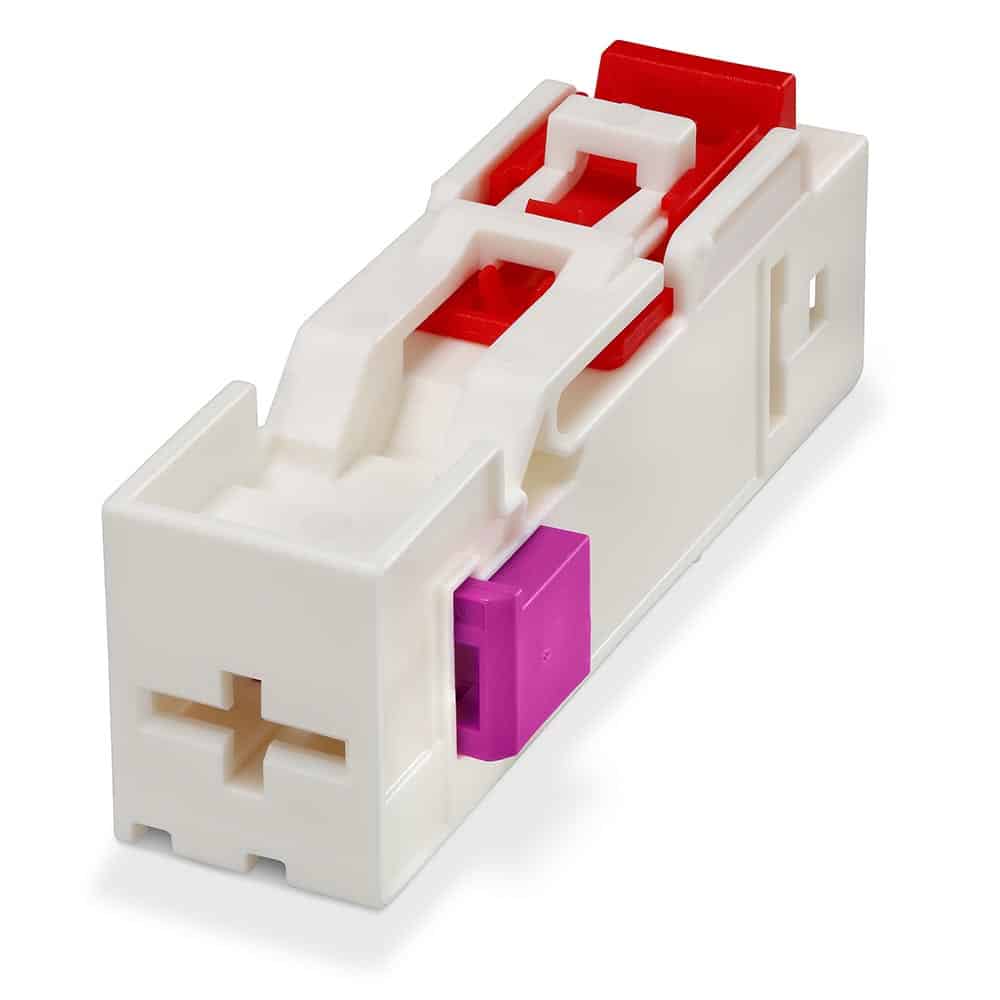

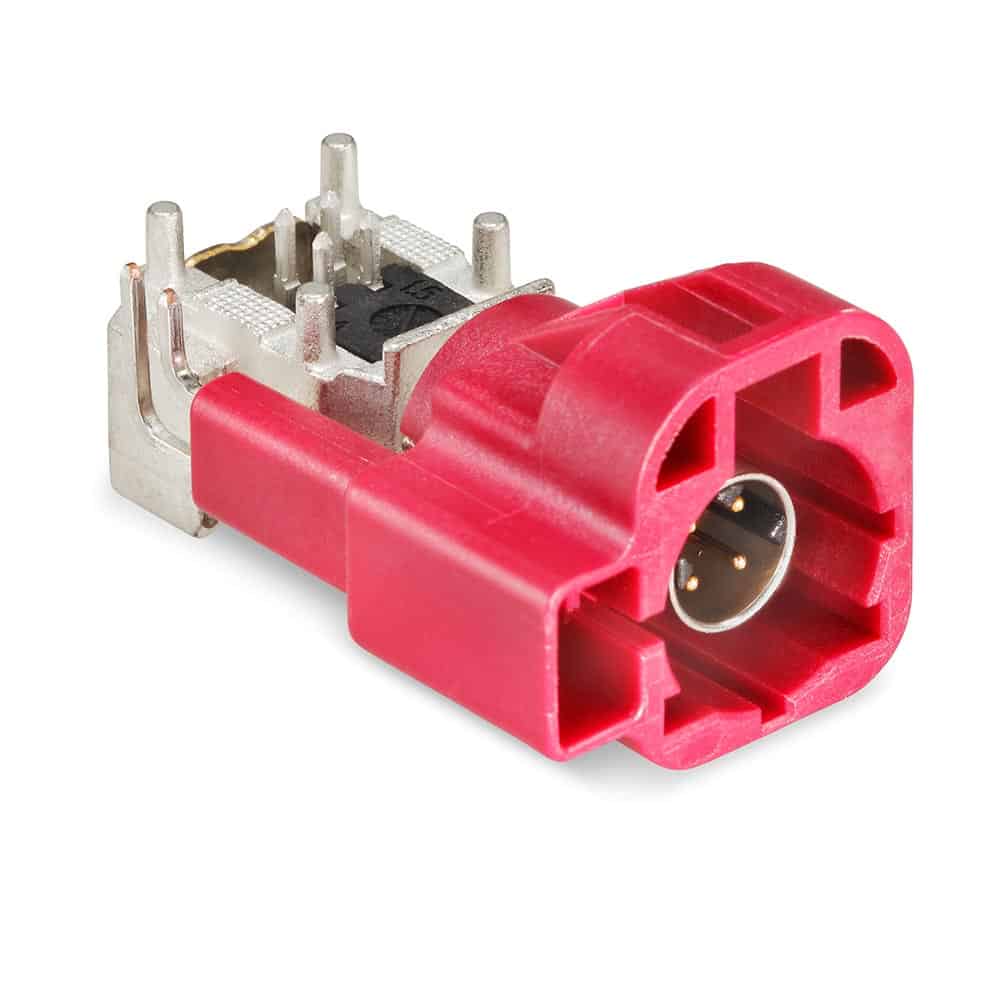

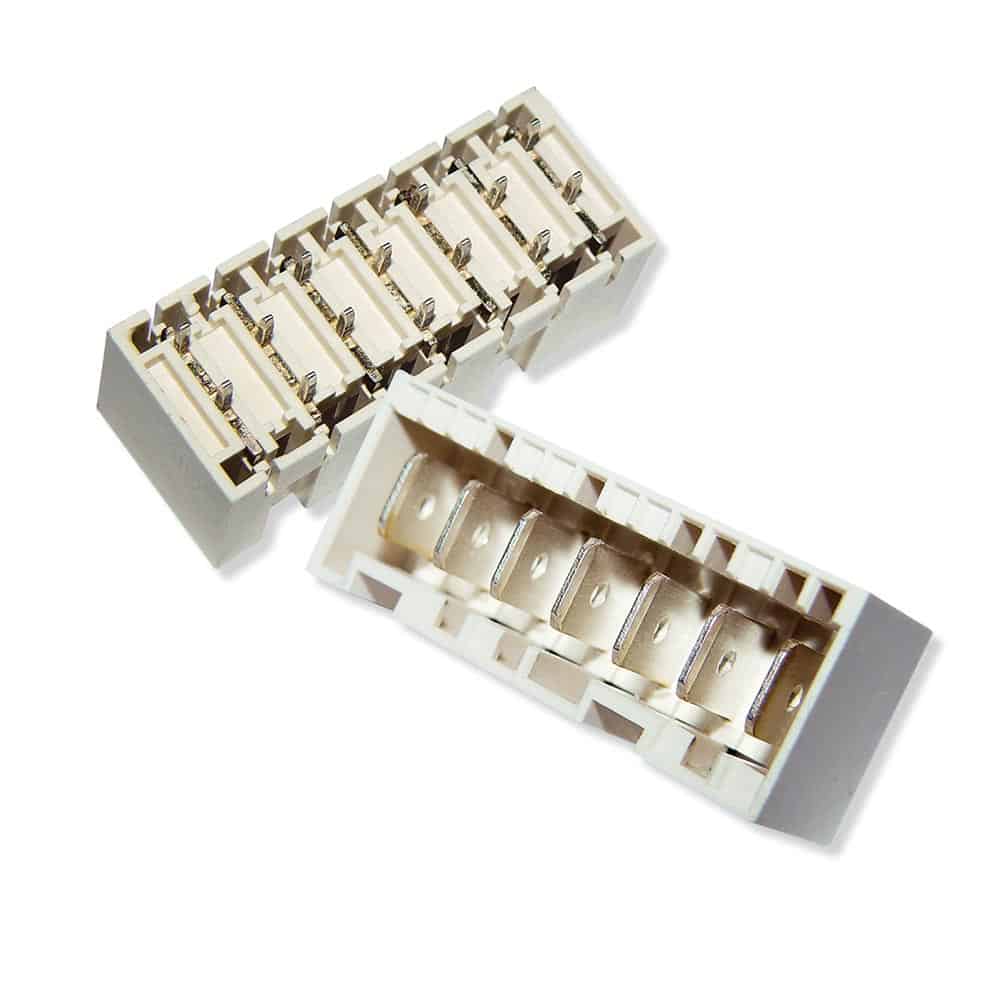

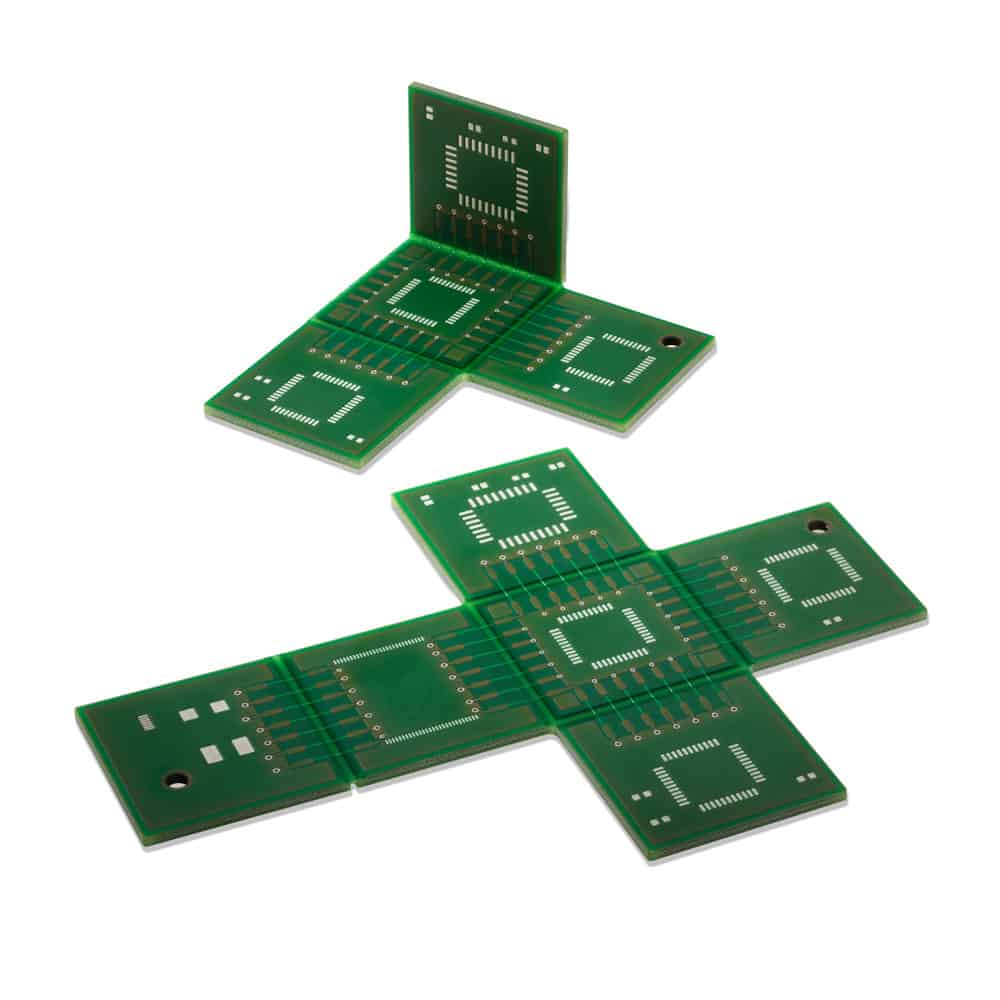

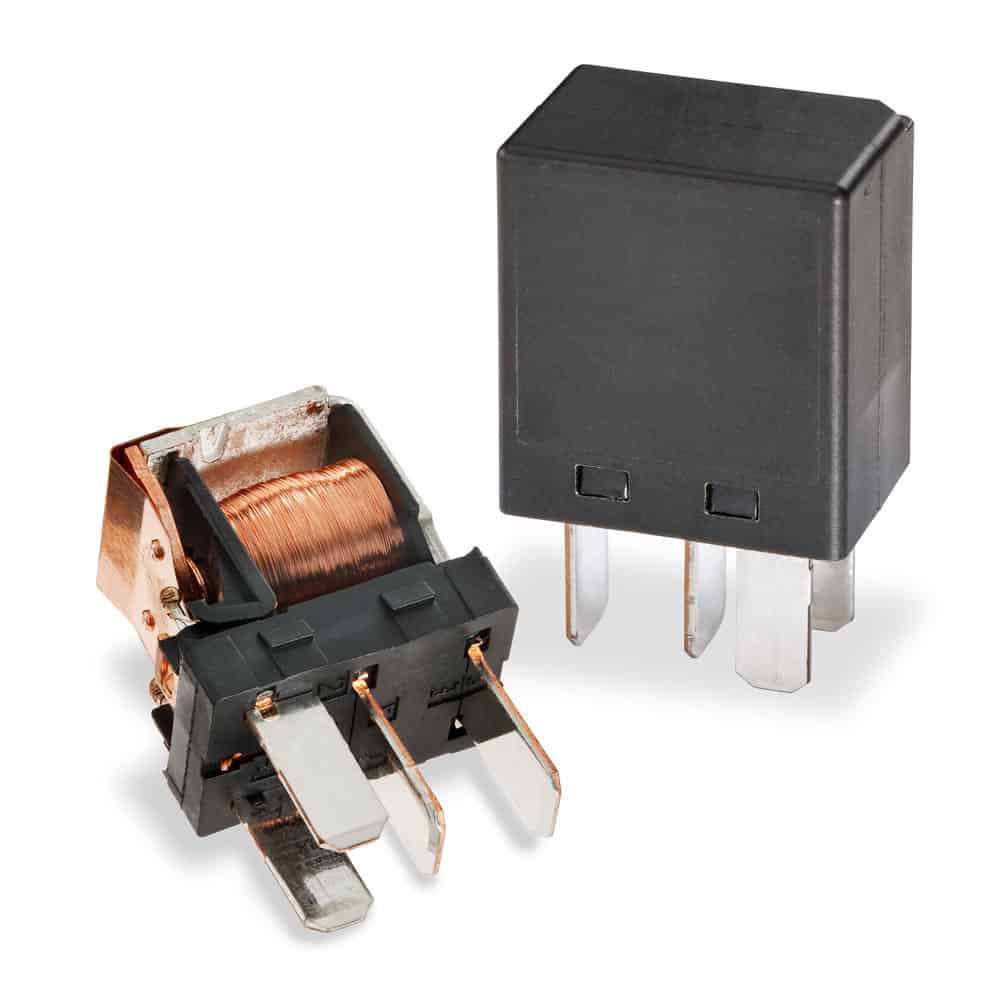

Electrotech & Electronics

Electronic and electro-mechanical components for a wide range of applications in modern devices and systems.

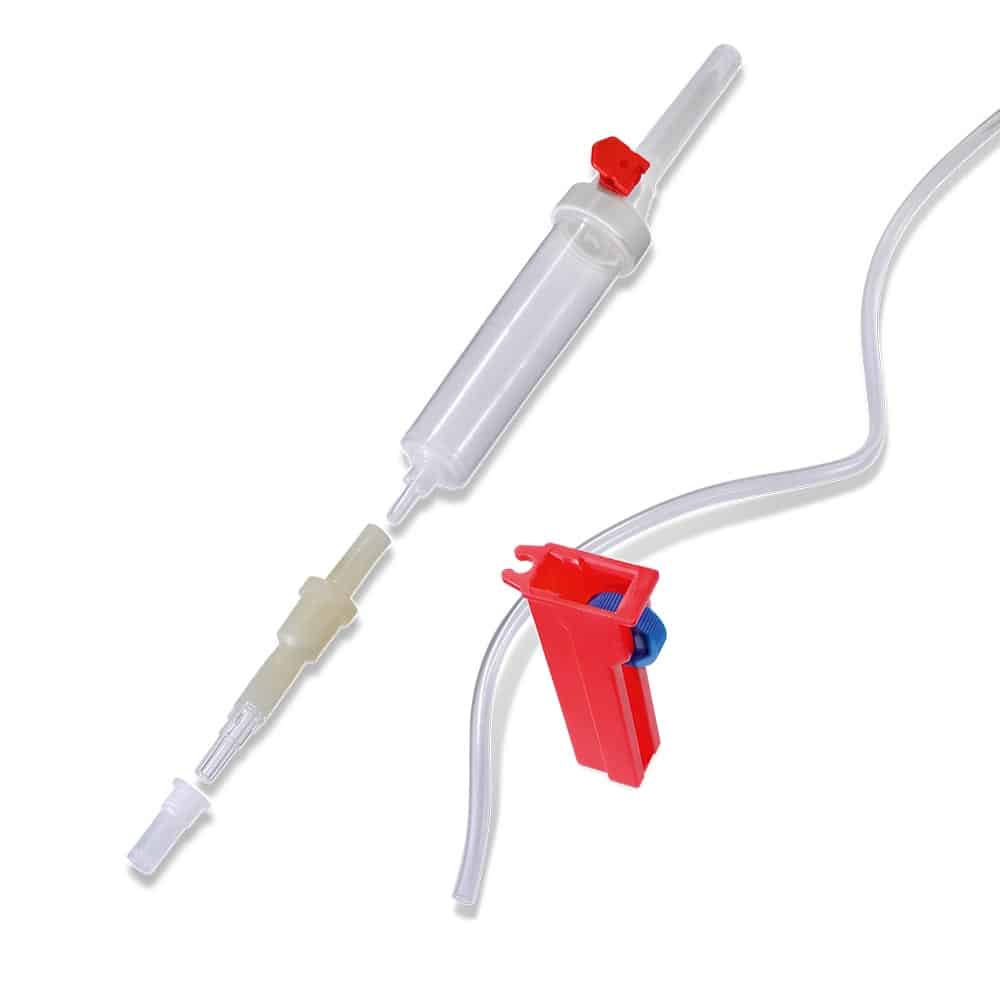

Healthcare & Life Sciences

Pharmaceutical and medical-technology products, produced according to the strictest pertinent standards of hygiene.

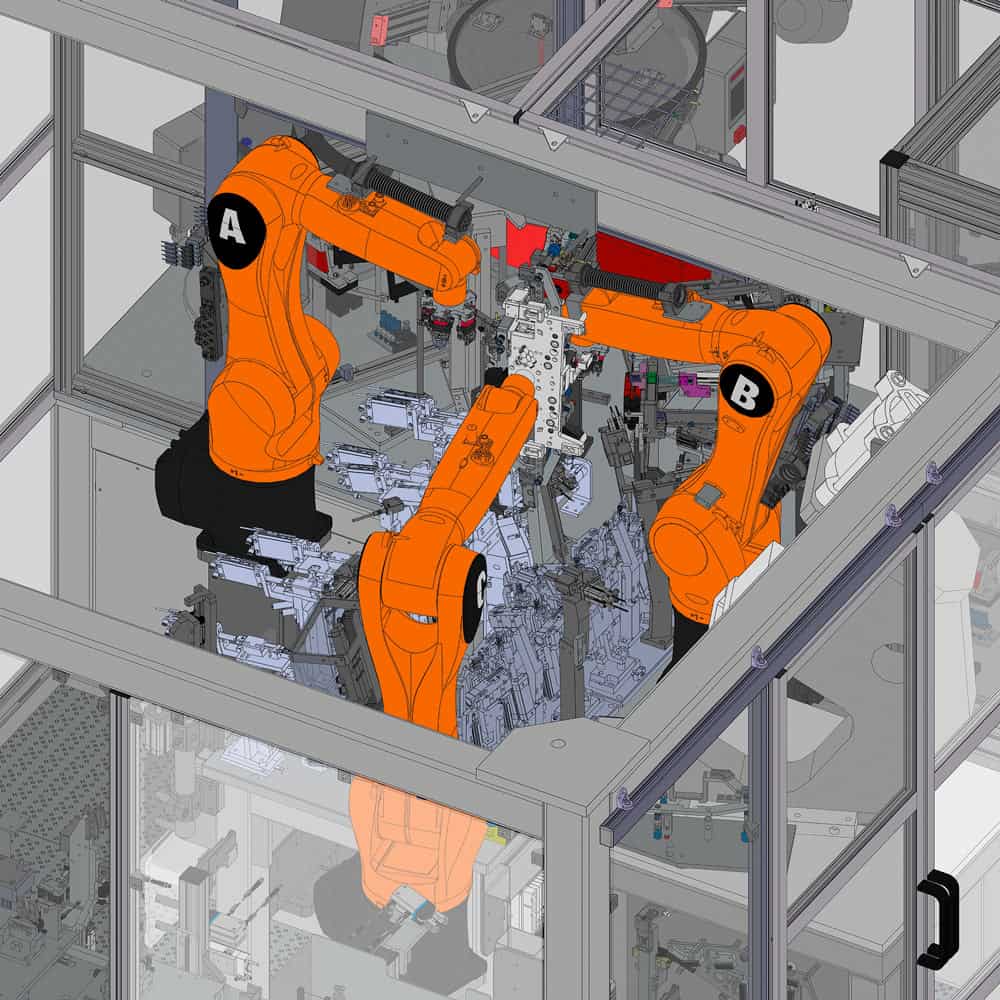

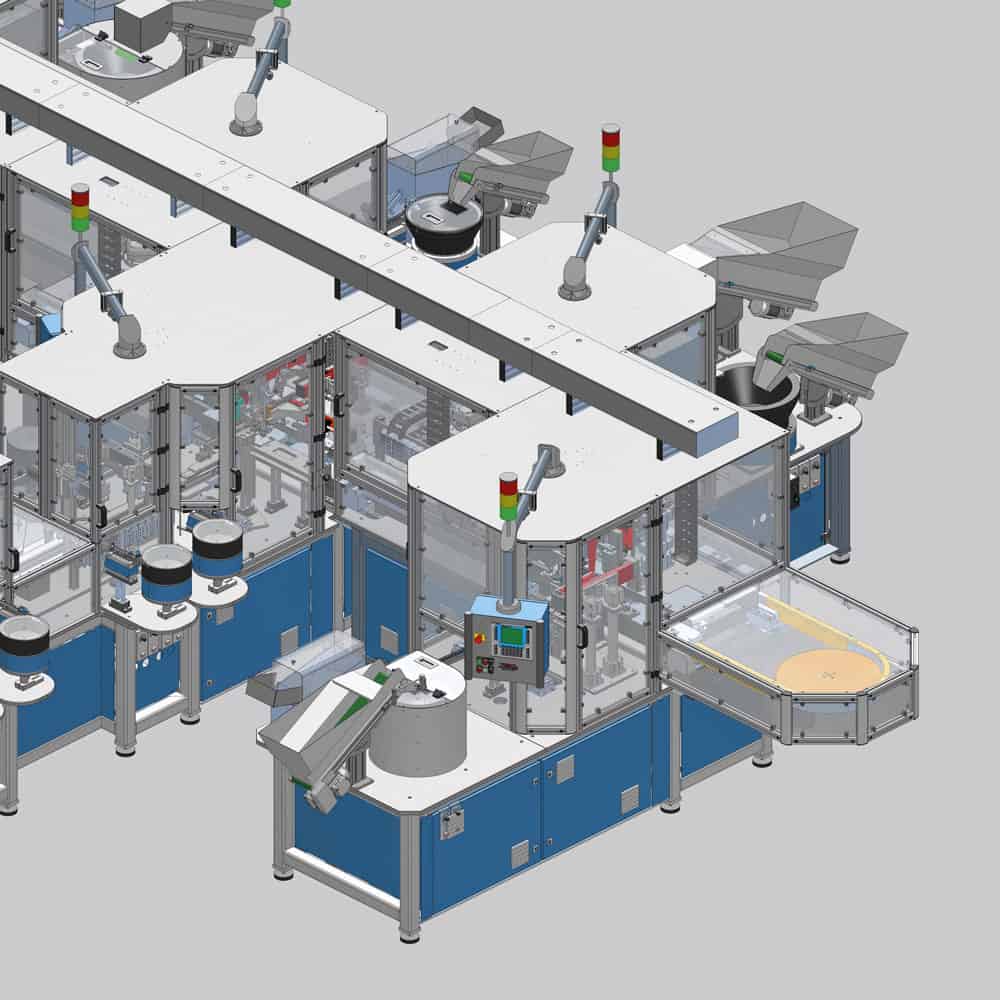

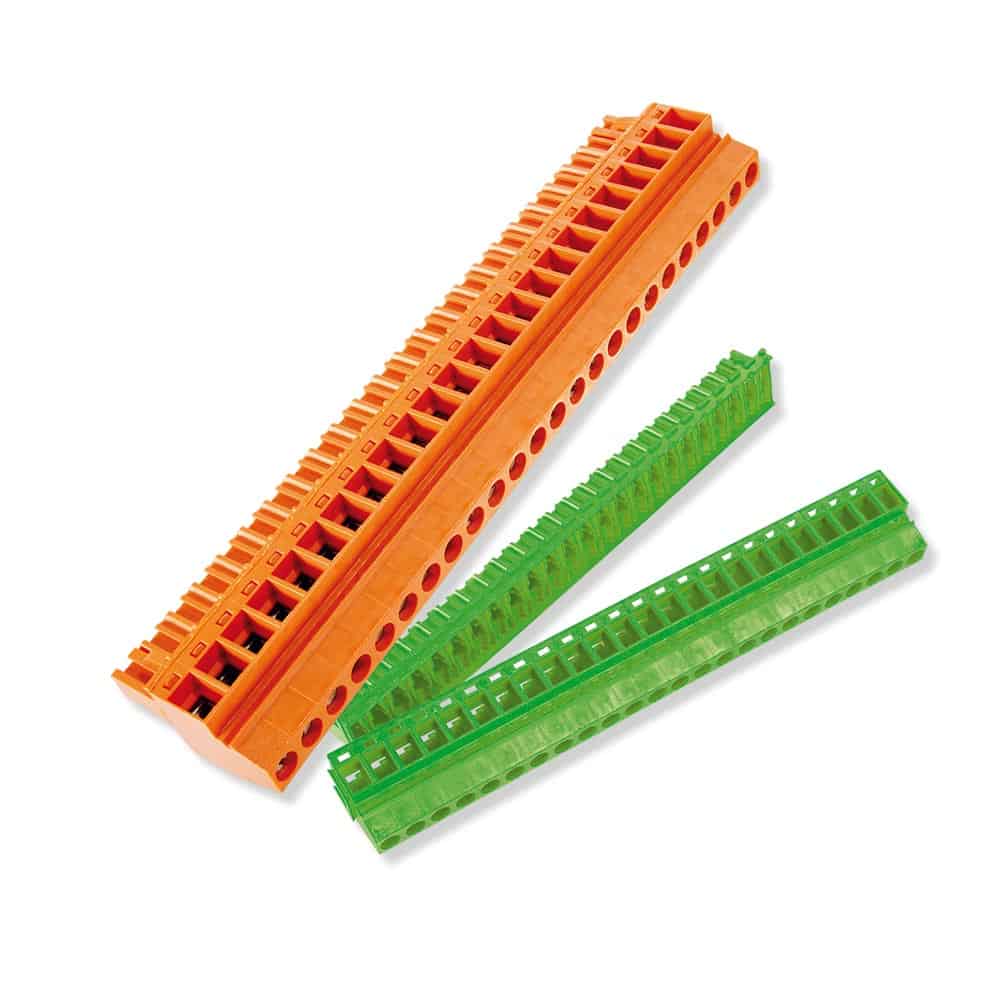

Solutions on demand

A wide variety of products, not only for end users: further applications for automated assembly systems from Autec.