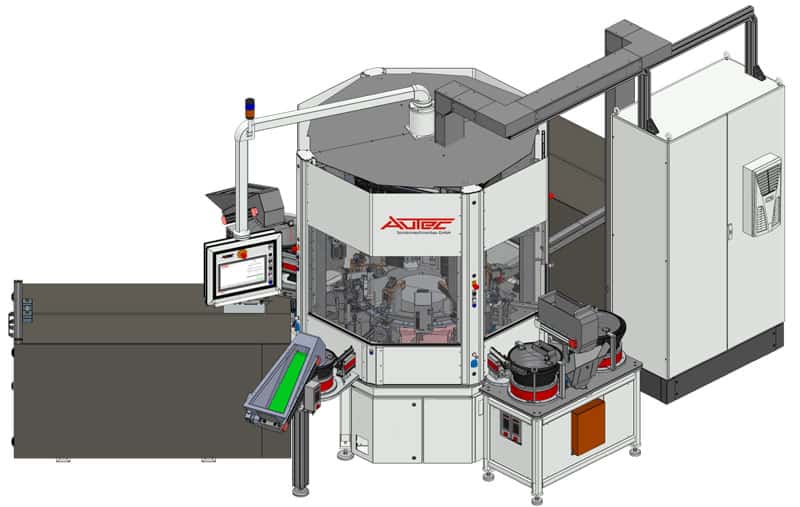

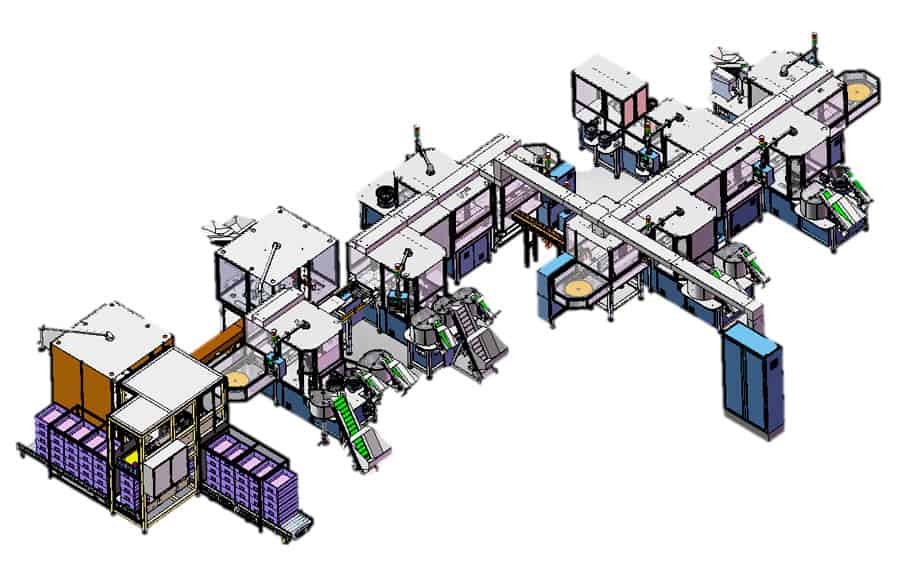

The connection to industrial communication interfaces makes systems from Autec “Industry 4.0-ready”: With data connection, you have all processes under constant control. For example, components can be tracked precisely, orders managed and evaluated. Dedicated software functions also enable intelligent energy management of your Autec automation system.

Downtime can be minimized thanks to remote diagnosis and parameterization. In the case of service, Autec offers computer-aided support via augmented reality.