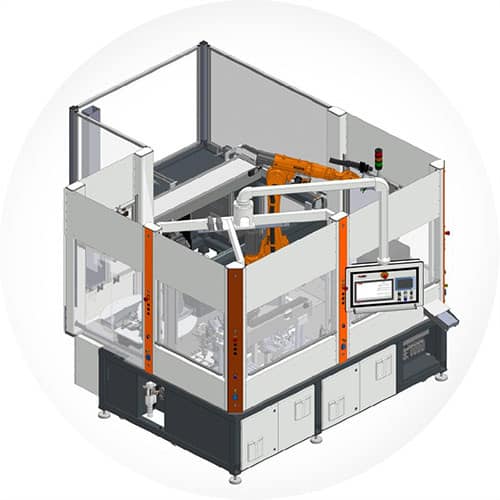

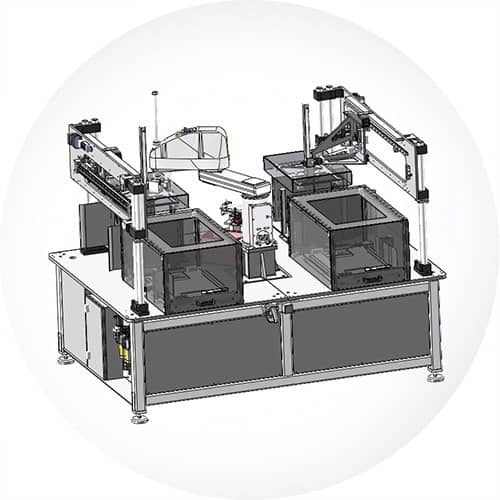

A variety of applications

Autec implements integrated automation solutions for most varied industries and applications. In the process from the component to the finished product (and beyond), numerous production steps can be integrated into Autec systems – from precise machining and assembly to testing, marking and palletizing.

According to your requirements, the selected technology ensures ideal clock rates and high flexibility. The highest possible standardization saves costs and time during implementation.

Process techniques

Handling

• Assembling

• Sorting

• Feeding

• Mounting

• Packaging

• Palletizing

Processing

• Greasing

• Casting

• Dispensing

• Pressing

• Stamping

• Screwing

• Separating

• Riveting

• Radial riveting

• Laser inscribing

• Embossing

• Pad printing

• Inkjet printing

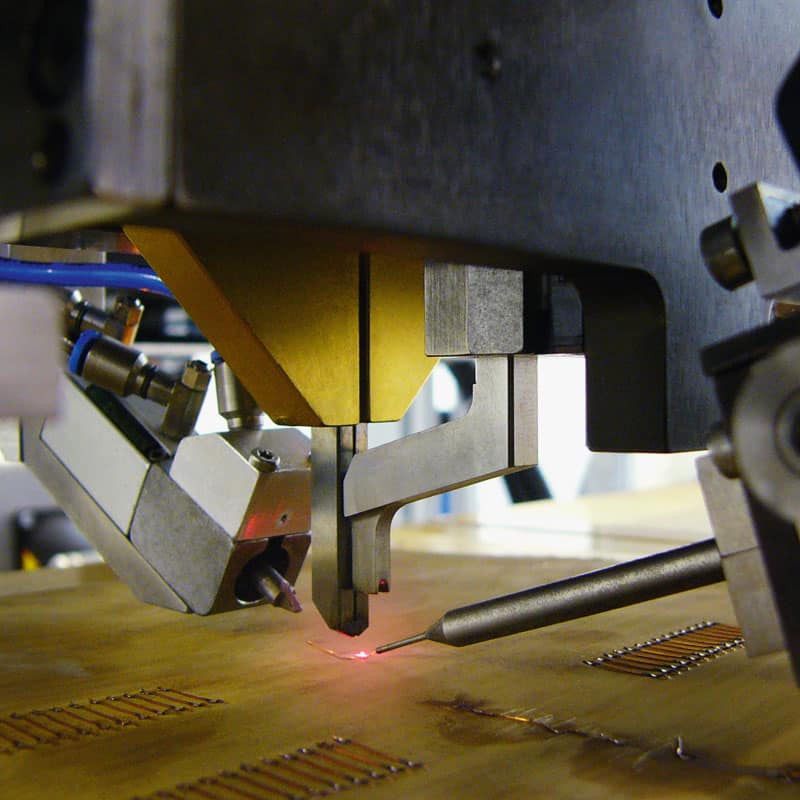

Welding

• Laser

• Ultrasonic

• Electric-resistance

• Gas-shielded

MEASURING AND TESTING

• End of Line-Testing (EOL)

• Leak Testing

• Torque Testing

• Continuity Testing

• HV Testing

• Camera Testing (AOI)

• Force-displacement Testing

• Mechanical Testing

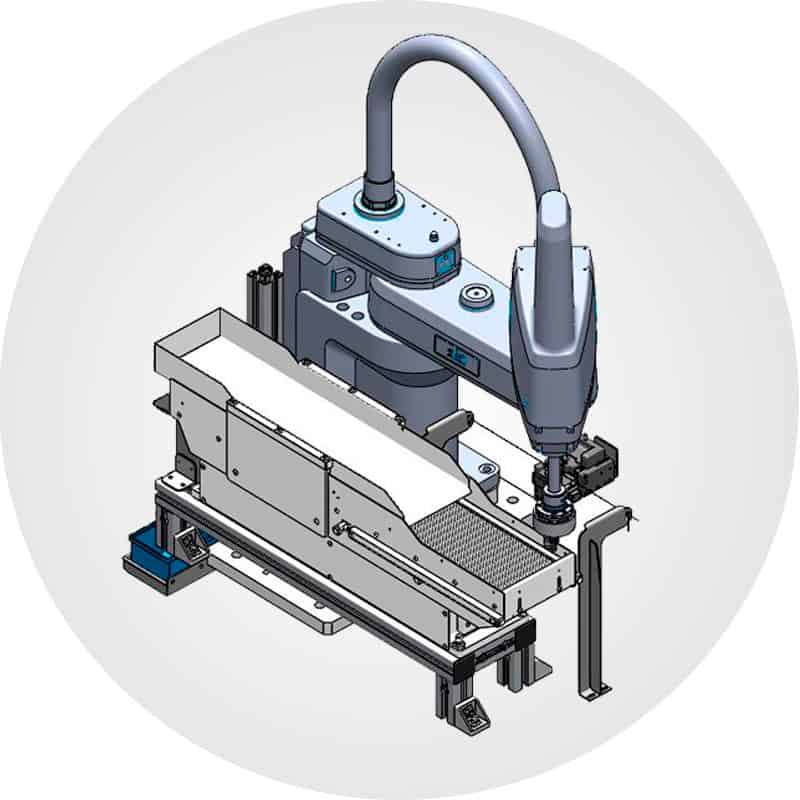

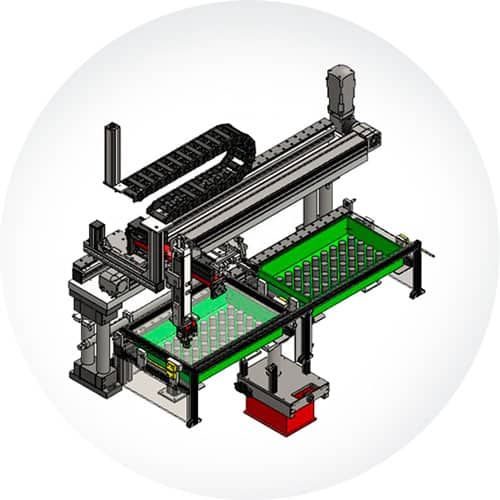

Autec feeding technology

High-quality, partly proprietary and manufactured component feeders ensure that your components are transported reliably, quickly and carefully in Autec systems. It makes no difference whether the handling of ordered or unordered components is involved.

Depending on the application, we offer a wide range of feed solutions for your automated assembly line:

Conveyor belts

Spiral conveyors

Step feeders

Centrifugal conveyors

Blister feeders

Pallet feeders

Flexible component feeders

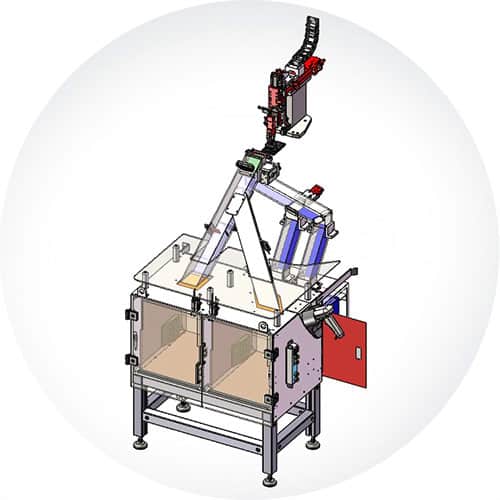

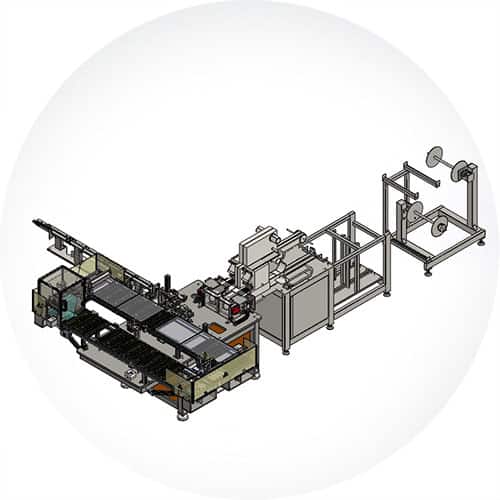

Autec Packaging Technology

Ready for transport: We also deliver tailor-made solutions for automated packaging after the assembly process, either downstream or as an integral part of your Autec production line.

Whether packed in standard containers, cartons or trays, whether blistered or as bulk solids – Autec packaging technology ensures optimal preparation of your product for onward transport.

Plastic standard containers

Boxes

Trays

Tape and Reel

Bulk packaging

Euro pallets

Small Load Carriers