March 10+11, 2026, Messe Friedrichshafen

Visit us: Booth B2-528

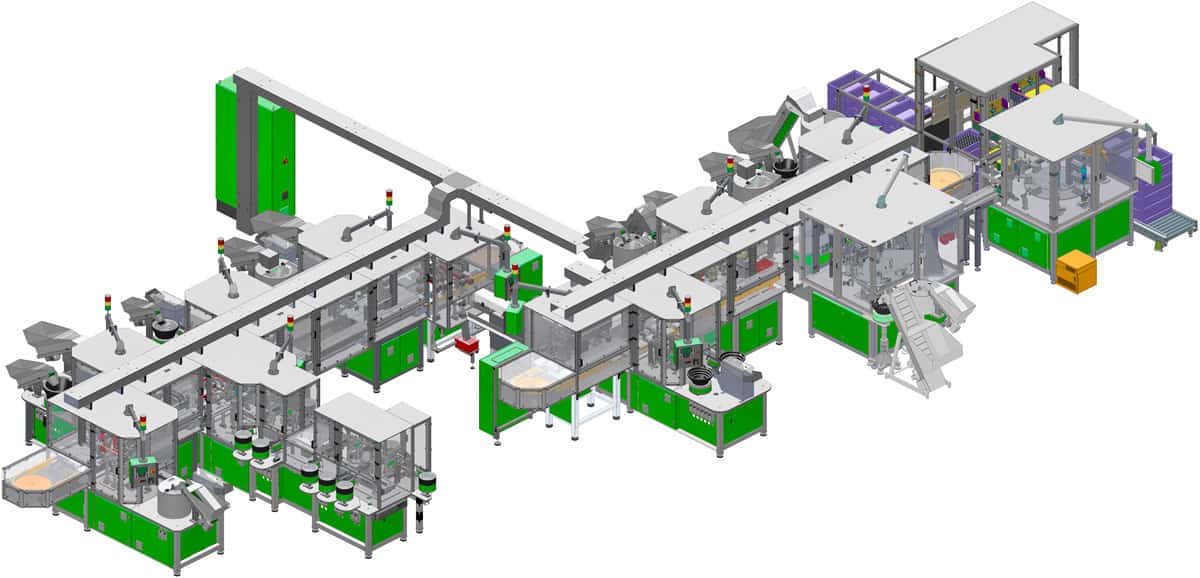

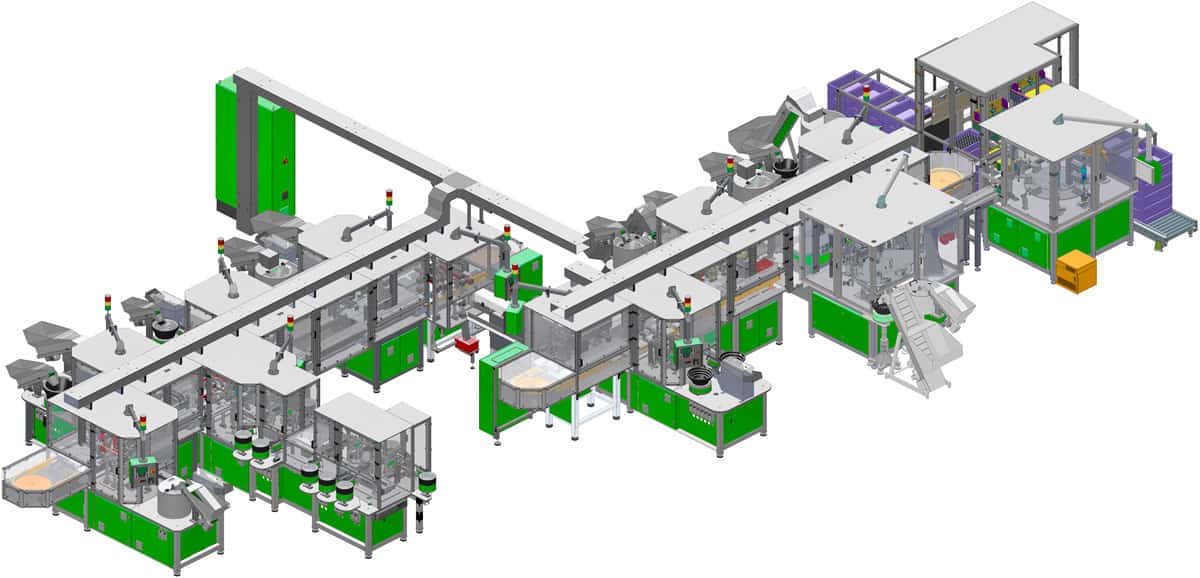

Special machine construction and automation

Automation from a single source

Automation from a single source

From concept to realization to commissioning and service

Flexible system concepts

Flexible system concepts

Precisely adaptable to your individual automation needs

Own

Feeding technology

Own feeding technology

Reliable and efficient feeding solutions for a wide range of components

Systems with high clock rates

Systems with high clock rates

Linear mounting systems for highest clock rates – without sacrificing quality

Minimal

Project times

Minimal

Project times

Thanks to in-house planning, manufacturing, assembly and programming

Worldwide

Service

Worldwide service

After-sales support from commissioning to maintenance and repair

Special Machine Construction 4.0

Autec automation systems offer practicable functions for data connection, acquisition and evaluation:

- Automated order management

- Data retrieval via mobile operating panels and smart devices

- Automatic process control, monitoring and evaluation

- Traceability

- Preventive maintenance

- Energy management

- Remote diagnosis and parameterization

- Computer-aided support, also via augmented reality

- Simple operation due to a specially developed Human Machine Interface (HMI)

Bundled competence

To ensure our high standards, we at Autec have extensive in-house development and manufacturing expertise. They enable us to achieve short reaction times, avoid frictional losses and ensure consistently high quality.

Autec Sondermaschinenbau GmbH already uses state-of-the-art processes in-house – e. g. for design, engineering, rapid prototyping and manufacturing:

- Fully comprehensive 3D design with optional virtual reality inspection

- Electrical and pneumatic planning by our own development team

- High-performance CNC 5-axis milling

- 3D printing, including for the construction of grippers and protective covers

- In-house programming of all control processes and user interfaces

Autec In-House Engineering

Ready for your requirements

We are happy to take on new challenges around your production automation: Thanks to many years of experience in special machine construction, Autec creates innovative technical solutions even for the most demanding problems.

Exemplary automation solutions from Autec:

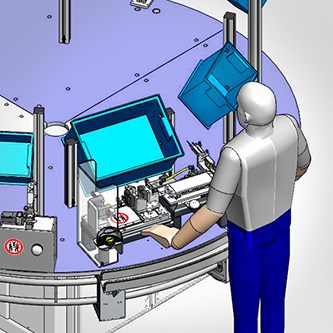

Partially automated Autec assembly line with specially developed, production-supporting workpiece carriers, thanks to which the workpiece remains freely rotatable and accessible.

Linear motor-driven transfer system whose magnetic movers allow individual movement profiles

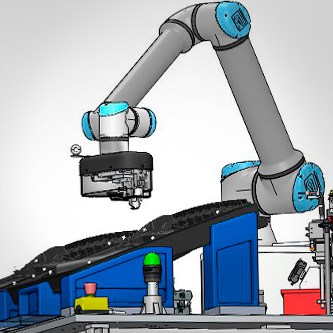

Innovative latching clip assembly system from Autec, whose closed force flow in the robot gripper prevents premature wear of the robot arm

Unique assembly concept with Autec’s own solution for cable handling – ideal for use in production processes for e-mobility and automotive applications

Special machines: Customised solutions for every production requirement

Special-purpose machinery – what exactly is it? And what can special-purpose machinery do in modern production environments?

You can find the most frequently asked questions and answers on the subject of special-purpose machinery in conjunction with Industry 4.0 in our FAQs:

Satisfied customers worldwide

Factory Automation from Autec stands the test every day – in a wide range of industries and production plants. As a full-service provider, we also offer commissioning, training and maintenance on site. Whether in Germany, Europe or worldwide.